Ⅰ Introduction

Generally speaking, OLEDs can be divided into two types according to light-emitting materials: small molecule OLEDs and polymer OLEDs (also known as PLEDs).

OLED is a device that uses a multilayer organic thin-film structure to generate electroluminescence. It is easy to manufacture and only requires a low driving voltage. These main features make OLED very prominent in meeting the application of flat-panel displays. OLED displays are lighter and thinner than LCDs. With high brightness, low power consumption, fast response, high definition, good flexibility, and high luminous efficiency, it can meet the new demands of consumers for display technology. More and more display manufacturers around the world have invested in research and development, which has greatly promoted the industrialization process of OLED.

Under the action of an electric field, the holes generated by the anode and the electrons generated by the cathode will move in the OLED and are injected into the hole transport layer and the electron transport layer respectively, and then migrate to the light-emitting layer. When the two meet in the light-emitting layer, energy excitons are generated, which excites the light-emitting molecules and finally produces visible light.

Ⅱ OLED classification

1 Classified by the device structure

OLED is a kind of organic electroluminescence device, which is composed of relatively special organic materials. According to its structure, it can be divided into four types, namely single-layer devices, double-layer devices, three-layer devices and multilayer devices.

(1) Single layer

The single-layer device is to insert a layer of the organic layer that can emit light between the anode and cathode of the device, and its structure is substrate/ITO/light-emitting layer/cathode. In this structure, due to the imbalance of electron and hole injection and transport, the efficiency and brightness of the device are low, and the stability of the device is poor.

(2) Double-layer

Double-layer devices are based on single-layer devices. Hole transport layers (HTL) or electron transport layers (ETL) are added on both sides of the light-emitting layer to overcome the problem of unbalanced carrier injection in single-layer devices and improve the device. The voltage-current characteristics of the device improve the luminous efficiency of the device.

(3) Three-layer

The three-layer device structure is the most widely used structure, and its structure is substrate/ITO/HTL/light-emitting layer/ETL/cathode. The advantage of this structure is that excitons are confined in the light-emitting layer, thereby increasing the efficiency of the device.

(4) Multi-layer

The multi-layer structure is a better structure, which can play the role of all levels. The light-emitting layer can also be composed of a multi-layer structure, and since the generator layers are independent of each other, they can be optimized separately. Therefore, this structure can give full play to the role of each organic layer, which greatly improves the flexibility of device design.

2 Classified by the driving method

OLEDs are divided according to driving methods and are generally divided into two types, one is the active type, and the other is the passive type. The active type is generally an active drive, and the passive type is a passive drive. In the actual application process, active drivers are mainly used for high-resolution products, while passive drivers are mainly used for displays with relatively small display sizes.

3 Classification based on materials

The materials that makeup OLEDs are mainly organic, which can be classified according to the types of organics, one is small molecules, and the other is polymers. The main difference between the two devices is the manufacturing process. The small molecule device mainly uses the vacuum thermal evaporation process, and the polymer device uses the spin coating or spray printing process.

Ⅲ OLED structure

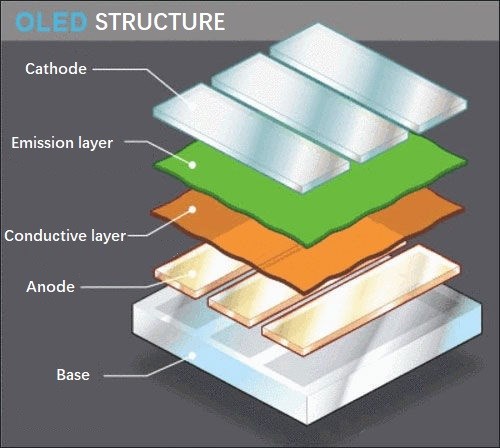

OLED structure

OLED devices are composed of substrate, cathode, anode, hole injection layer (HIL), electron injection layer (EIL), hole transport layer (HTL), electron transport layer (ETL), the electron blocking layer (EBL), the hole blocking layer (HBL), light-emitting layer (EML) and other parts. Among them, the substrate is the basis of the entire device, and all functional layers need to be vapor-deposited on the substrate of the device; glass is usually used as the substrate of the device, but if you need to make a bendable flexible OLED device, you need to use other materials, such as plastic, etc. The substrate of the device. The anode is connected to the positive electrode of the device with an external driving voltage. The holes in the anode will move to the light-emitting layer in the device under the drive of the external driving voltage. The anode needs to have a certain degree of light transmission when the device is working so that the light emitted inside the device can be observed by the outside world; the most commonly used material for the anode is ITO. The hole injection layer can modify the anode of the device, and can smoothly inject the holes from the anode into the hole transport layer; the hole transport layer is responsible for transporting holes to the light-emitting layer; the electron blocking layer will transfer the holes from the cathode.

Electrons are blocked at the interface of the light-emitting layer of the device, increasing the concentration of electrons at the interface of the light-emitting layer of the device. The holes of the anode are blocked at the interface of the light-emitting layer of the device, thereby increasing the probability of recombination of electrons and holes at the interface of the light-emitting layer of the device, increasing the luminous efficiency of the device. The electron transport layer is responsible for transporting electrons from the cathode to the light-emitting device of device. The electron injection layer plays the role of modifying the cathode and transferring electrons to the electron transport layer. The electrons in the cathode will move to the light-emitting layer of the device under the driving voltage applied to the device and then move between the light-emitting layer. The electrons then recombine with holes from the anode in the light-emitting layer.

Ⅳ OLED Principle

The light-emitting process of OLED devices can be divided into the injection of electrons and holes, transport of electrons and holes, recombination of electrons and holes, and de-excitation light of excitons. Specifically:

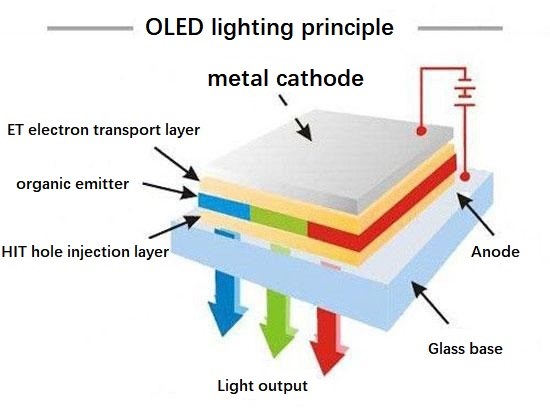

OLED lighting principle diagram

(1) Injection of electrons and holes. The electrons in the cathode and the holes in the anode will move to the light-emitting layer of the device under the drive of an external driving voltage. During the process of moving to the light-emitting layer of the device, if the device contains an electron injection layer and a hole injection layer, then electrons and holes must first overcome the energy barrier between the cathode and the electron injection layer and the anode and the hole injection layer, and then move to the electron transport layer and hole transport layer of the device through the electron injection layer and the hole injection layer; The electron injection layer and the hole injection layer can increase the efficiency and lifetime of the device. The mechanism of electron injection in OLED devices is still under constant research, and the most commonly used mechanisms are the and the interface dipole mechanism.

(2) Transport of electrons and holes. Driven by an external driving voltage, electrons from the cathode and holes from the anode will move to the electron transport layer and hole transport layer of the device respectively, and the electron transport layer and hole transport layer will move the electrons and holes to the device respectively at the interface of the light-emitting layer. At the same time, the electron transport layer and the hole transport layer will block the holes from the anode and the electrons from the cathode at the interface of the light-emitting layer of the device, so that the electrons and holes at the interface of the light-emitting layer of the device are accumulated.

(3) The recombination of electrons and holes. When the number of electrons and holes at the interface of the light-emitting layer of the device reaches a certain number, the electrons and holes will recombine and generate excitons in the light-emitting layer.

(4) The de-excitation light of excitons. The excitons generated in the light-emitting layer will activate the organic molecules in the light-emitting layer of the device, which in turn causes the electrons in the outermost layer of the organic molecules to transition from the ground state to the excited state. Because the electrons in the excited state are extremely unstable, they will move to the ground state. During the transition, energy is released in the form of light during the transition, and the device emits light.

Ⅴ OLED characteristics

The reason why OLED technology can be widely used is that it has the following advantages compared with other technologies:

(1) Low power consumption

Compared with LCD, OLED does not require a backlight, which is a more energy-consuming part of LCD, so OLED is more energy-efficient. For example, the power consumption of a 24in AMOLED module is only 440mw, while a 24in polysilicon LCD module reaches 605mw.

(2) Fast response

Compared with other technologies, OLED technology has a fast response speed, and the response time can reach the microsecond level. The higher response speed achieves better moving images. According to relevant data analysis, its response speed has reached about 1000 times the response speed of liquid crystal displays.

(3) Wide viewing angle

Compared with other displays, because OLED is actively emitting light, the picture will not display distortion in a large viewing angle range. The vertical and horizontal viewing angles exceed 170 degrees.

(4) Able to achieve high-resolution display

Most high-resolution OLED displays use active matrix, or AMOLED, whose light-emitting layer can absorb 260,000 true colors with high resolution, and with the development of science and technology, its resolution will be higher in the future.

(5) Wide temperature characteristics

Compared with LCD, OLED can work in a large temperature range. According to relevant technical analysis, the temperature can be operated normally from -40 degrees Celsius to 80 degrees Celsius. In this way, geographical restrictions can be reduced, and it can be used normally in extremely cold regions.

(6) OLED can realize soft screen

OLEDs can be produced on different flexible substrate materials such as plastics and resins. The organic layer is vapor-deposited or coated on a plastic substrate to realize a soft screen.

(7) The quality of the finished OLED is relatively light

Compared with other products, OLED has a smaller quality and a smaller thickness than LCD. Its seismic coefficient is higher, and it can adapt to harsher environments such as greater acceleration and vibration.

Ⅵ OLED applications

Because OLED has many advantages, OLED technology has a wider application range than LCD technology and can be extended to the fields of electronic products, commercial fields, transportation, industrial control, and medical fields. In addition, in recent years, major international companies have continued to strengthen the research on OLED technology, OLED technology will be further improved.

In the commercial field, small-sized OLED screens can be installed in POS machines, copiers, and ATM machines. Because of the characteristics of OLED screens such as bendability, lightness and thinness, and strong anti-aging performance, they are both beautiful and practical. Large screens can be used as business promotion screens, as well as advertising screens in stations and airports. This is because OLED screens have wide viewing angles, high brightness, and bright colors, and their visual effects are much better than LCD screens.

In the field of electronic products, OLED is most widely used in smartphones, followed by notebooks, display screens, TVs, flat-panel, digital cameras, and other fields. Because OLED displays have more intense colors and can adjust the colors (different display modes). Therefore, it is very widely used in practical applications, especially today's curved TV, which is widely praised by the masses.

There is a bit of VR technology to mention here. LCD screens have very serious smears when viewing VR devices, but they will alleviate a lot in OLED screens. This is because OLED screens light up light molecules, while liquid crystals flow through light. Therefore, in 2016, OLED screens officially surpassed LCD screens and became the new darling of the mobile phone industry.

In the transportation field, OLEDs are mainly used for ships, aircraft instruments, GPS, video phones, car displays, etc., and are mainly small in size. These fields mainly focus on the wide viewing angle performance of OLEDs, which can be seen clearly even if you don’t look directly at the screen content.

In the medical field, the impact of medical diagnosis and surgical screen monitoring are inseparable from the screen. In order to meet the wide-view requirements of medical displays, OLED screens are the "one choice."

It can be seen that the development space of the OLED display is very high, and the market potential is huge. However, compared with LCD screens, OLED manufacturing technology is not mature enough. Due to the low mass production rate and high cost, only some high-end devices on the market will use top OLED screens. However, judging from the data in the first half of 2017, various manufacturers have increased their investment in OLED technology research, and many mid-end electronic products have applied OLED displays. From the perspective of the mobile phone industry, since 2015, the proportion of OLED screen applications has increased year by year. Although there are still not as many LCD products, high-end smartphones have adopted the most advanced OLED screens. Therefore, the development of electronic products such as smartphones is bound to further promote the development of OLED.

- Prev:None

- Next:Stacked LED for fully immersive virtual reality display

-

Tel

13824346118 -

Whatsapp

ENGLISH

ENGLISH 简体中文

简体中文